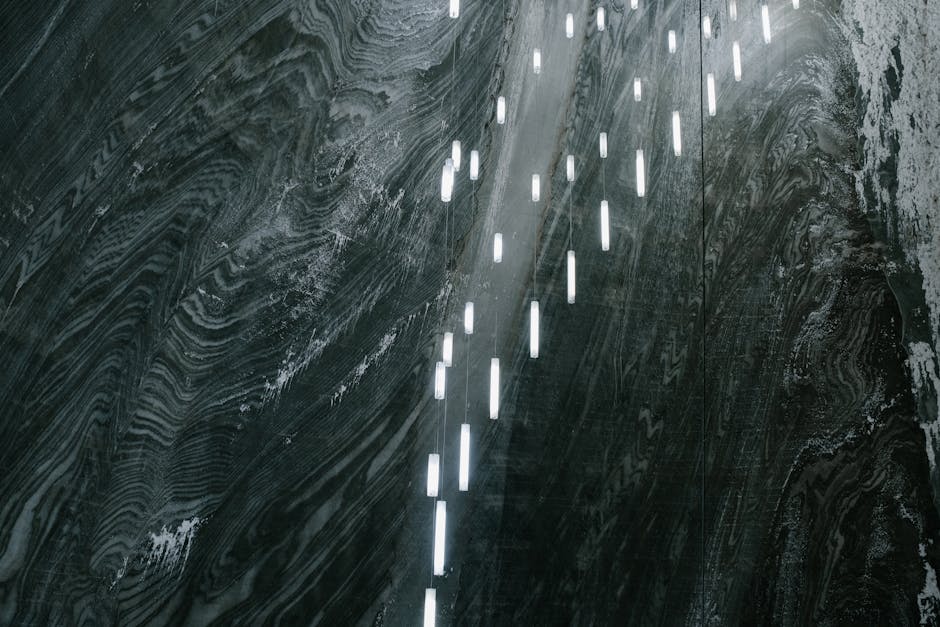

Introduction to Industrial LED Lighting

LED lighting is becoming popular in industries due to its energy efficiency and long lifespan. In London, manufacturers are increasingly adopting Industrial LED Lighting for sustainable practices. LED lights consume less energy, have a longer life span, and provide better illumination compared to traditional lighting. The use of Industrial LED Lighting helps companies reduce their carbon footprint and lower energy costs.

Benefits of Industrial LED Lighting

LED lighting in industries offers numerous benefits beyond traditional lighting methods. Here are some advantages of industrial LED lighting:

-

LED lights consume less energy, leading to cost savings on electricity bills.

-

They have a longer lifespan compared to traditional lighting, reducing maintenance costs.

-

LED lights produce less heat, creating a more comfortable working environment.

-

These lights are more environmentally friendly as they are energy-efficient and emit less carbon dioxide.

-

LED lights provide better illumination, improving visibility and productivity in industrial settings.

Energy Efficiency in Manufacturing

In the manufacturing industry, energy efficiency plays a crucial role in reducing operational costs and lowering the environmental impact. By utilizing industrial LED lighting, companies in London can significantly decrease energy consumption, leading to long-term cost savings and a more sustainable manufacturing process. LED lights use less energy and have a longer lifespan compared to traditional lighting sources, making them an ideal choice for enhancing energy efficiency in manufacturing facilities. By investing in energy-efficient lighting solutions, manufacturers in London can contribute to a greener future while improving their bottom line.

Impact on Sustainable Practices

The use of industrial LED lighting in London manufacturing plays a significant role in promoting sustainability. LED lights consume less energy compared to traditional lights, which helps reduce overall energy consumption in manufacturing facilities. This, in turn, lowers carbon emissions and contributes to a more eco-friendly operation. LED lights also have a longer lifespan, reducing the frequency of replacements and overall waste generation. By implementing LED lighting, London manufacturers can effectively reduce their environmental impact and move towards more sustainable practices.

Implementing Industrial LED Lighting

When implementing industrial LED lighting in manufacturing practices in London, companies can significantly reduce energy consumption and maintenance costs. LED lights are energy-efficient and have a longer lifespan compared to traditional lighting options. By making the switch to LED lighting, businesses can contribute to a more sustainable environment while also improving the quality of light in their facilities. LED lighting is a smart investment that can positively impact both the bottom line and the environment.

Cost Considerations

LED lighting may cost more initially, but in the long run, it can save you money on energy bills. LED lights use less electricity and have a longer lifespan than traditional lighting options. The initial cost of LED lights can range from (20 to )100 per bulb, but they can last up to 25 times longer than traditional bulbs. Additionally, LED lights require less maintenance, which can further reduce long-term costs.

Case Studies in London Manufacturing

London manufacturers are implementing LED lighting solutions to improve sustainability practices. Case studies show significant energy and cost savings achieved by switching to industrial LED lighting. These studies highlight the positive impact of LED lighting on reducing carbon footprint and enhancing operational efficiency in the manufacturing sector.

Importance of Proper Lighting Design

Good lighting design is crucial in manufacturing facilities to ensure the safety of workers and the efficiency of operations. Proper lighting can improve productivity, decrease errors, and enhance the overall working environment. In a manufacturing setting, industrial LED lighting is preferred due to its energy efficiency, longevity, and ability to provide bright and even illumination. LED lights also contribute to sustainability efforts by consuming less energy and having a longer lifespan compared to traditional lighting options. Effective lighting design plays a significant role in creating a productive and sustainable manufacturing environment in London.

Maintenance and Longevity

LED industrial lights are known for their long lifespan, requiring minimal maintenance. Compared to traditional lighting, LED lights can last up to 50,000 hours. This longevity not only reduces the frequency of replacements but also lowers maintenance costs over time. LED lights are energy-efficient, meaning they consume less power, resulting in further cost savings in the long run.

Conclusion and Future of LED Technology

LED technology continues to play a pivotal role in enhancing sustainability in London’s manufacturing sector. As industries strive towards more eco-friendly practices, the future of LED lighting looks promising. Innovations in LED technology are expected to further increase energy efficiency and reduce carbon footprints. The widespread adoption of industrial LED lighting is anticipated to drive significant cost savings for businesses while also contributing to a greener environment. As manufacturers in London embrace these sustainable practices, the future of LED technology appears to be bright, illuminating a path towards a more sustainable and environmentally conscious future.