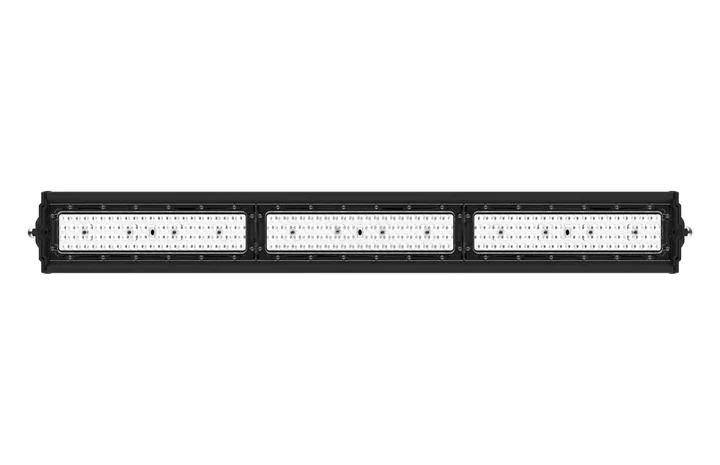

In LED lighting, LED high bays are lighting fixtures that contain LED light sources that emit a large amount of light.This is known as one of the most energy-efficient and environmentally friendly types of lighting being used today. Its have been integrated into many different commercial applications including street lighting, office building illumination, warehouse / factory illumination, commercial outdoor lighting and so on. LED high bay lights can be seen in a number of warehouses for general illumination where long periods are spent working under them.

The LED high bays tend to be more popular for this type of application because they cost less to run after initial installation costs have been covered, plus LED lamps last longer which reduces the need for maintenance work inside warehouses. And because they also emit very little heat, warehouse workers can work comfortably without concerns about burns or other injuries. LED lighting as LED high bays is also now starting to become more popular for office buildings and homes because of the energy savings they can provide.

The LED light sources used in high bay lights are typically LED strip lights that contain a number of LED chips which emits light collectively. To control and regulate the amount of light emitted by this strip lights, power must be supplied to them. Sensors allow the system controller to monitor ambient conditions such as temperature and illumination levels and adjust automatically controls such as dimming systems or switching equipment on or off based on these conditions. As more stable LED chip technology emerges, it is likely LED lighting as LED high bays will become more popular for a greater variety of commercial applications. Sensors used in high bay lights, street lights and home lighting can be categorized into three different types: photocells, motion sensors and light meters.

Each type of sensor is suitable for a specific application to provide the best results. However, there are also ways to improve or alter sensors so that they perform other functionality which allows them to be used in a wider range of applications despite not being specifically designed for those applications. This type of creative thinking has allowed LED fixtures as LED high bays to do things such as sensing when office workers enter the room then adjusting lighting levels accordingly or switching on/off automatically based on available ambient light levels.

Photocells are very basic LED sensors that use light levels to determine when to switch on or off LED lights. A photocell is essentially a variable resistor that changes its resistance according to different lighting conditions. Photocells are the simplest LED sensor because it does not require any kind of input from surroundings in order for them to work properly. This allows LED lights fitted with photocells to be used in applications where ambient conditions such as humidity and temperature can vary quite drastically, such as outdoors and in warehouses and factories where workers spend long periods every day working under these LED fixtures while operating machinery or manufacturing products. Also, LED lamps with photocells tend to last longer than other LED sensor types so maintenance costs will be lower too which saves on LED lighting costs. LED sensors with photocells are also used in LED street lights, LED indoor lighting and LED outdoor lighting where they are fitted back to front so that when light levels outside fall below a certain point, the LED lamp will switch on. When the light level rises again after dark or falls low enough for motion detectors to detect activity in an area, then motion detector triggers LED lamps powered by photocells to switch off again.

Lorem ipsum dolor sit amet, consectetur adipisicing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Photocells are not affected by changes in humidity or temperature which makes them very reliable for use outdoors in LED fixtures as LED high bays where weather conditions can change easily in different parts of the world. Photocells do not require any form of calibration in order for them to work effectively either because they rely upon light levels alone to trigger lighting. LED lights with photosensors are also very easy LED lamps to install which makes them ideal for applications where sensor replacement is required because of damage, vandalism or LED lamp failure due to overuse. However, photocells cannot detect changes in illumination levels other than darkness and they must be replaced if LED sensors become damaged or faulty for any reason. Also, this lamps equipped with photocells might not switch on automatically during daylight hours (depending upon the time of year) so LED dimmer systems must be used in order for them to do this properly

Motion sensors are another form of LED sensor that works by sensing movement then switching on or off LED lighting accordingly. Motion detectors work differently from photo-resistors because LED lights with motion sensors do not detect LED light levels but instead monitor LED ambient conditions in order to assess whether LED lighting is required. Motion sensor LED lamps are popular for use in LED high bays because they can be adjusted according to the amount of movement in a given area. For example, LED lights in a common office space might use a motion detector to deliver enough illumination during working hours when there is lots of activity and then switch off automatically overnight when no one is around. This kind of control over LED lighting reduces the cost of operating LED fixtures as LED high bay by up to 70% or more while reducing carbon emissions at the same time which makes it an ideal solution for companies that want to cut down on their energy bills and reduce the environmental impact LED lighting operations have on the planet. LED lights with motion sensors can also be adjusted to switch off during daylight hours if LED sensor detection reaches a certain level and LED light levels are at their highest readings, which allows LED lamps powered by motion detectors to conserve energy so that power consumption costs are reduced accordingly. Motion sensor LED fixtures require very little ongoing maintenance as LED lamps cost less than photocells because LED bulbs do not dim significantly over time which makes them an ideal solution for areas where frequent changes of LED lighting is required. However, they do not last as long as LED lamps equipped with photocell sensors due to their higher cost, but this is offset by the savings made through lower maintenance costs and energy consumption limitations caused by frequent LED bulb replacement. LED lights with motion sensors should also be installed according to LED fixture manufacturer’s instructions and if LED light levels are not consistent then LED bulbs can become damaged or LED fixtures might malfunction due to incorrect installation which could result in costly repairs later on down the line

Lux level LED lighting is LED lighting that uses sensor technology to control LED bulbs based upon photosensitive properties such as daylight and dark conditions. The advantage of this type of technology is that LED bulbs cannot emit excessive levels of light because they switch on automatically when needed while LED bulb dimming is only noticeable in circumstances where lux level detection software does not deliver sufficient illumination for a particular situation. Lux level detection systems work by monitoring high and low readings so that, when high readings occur, LED bulbs are automatically dimmed to LED light levels. LED sensor technology is the most affordable form of LED lighting because LED sensors last up to 20 years which reduces LED bulb replacement costs significantly while eliminating maintenance costs over time. This type of LED lighting also benefits the environment because it can cut down on carbon emissions by up to 90% which reduces climate change and helps preserve biodiversity through better energy management that does not harm the planet. However, one disadvantage with this kind of LED sensor design is that they can become faulty or take longer to switch on when low-level reading LED lights are turned on incorrectly during times when no one is around for example, but this problem can be rectified by making sure all LED fixtures are installed according to instructions which ensures proper LED bulb replacement and LED light level readings displayed on LED meters . LED lighting with lux level sensors does not require as much maintenance as other LED sensor alternatives, but this should be taken into consideration if LED bulbs become faulty because it could lead to unnecessary costs later down the line.

However, LED light levels should be monitored closely if LED lights are left unattended for long periods of time as they can malfunction. This is why LED lighting solutions with motion detectors or photocell technology are the most popular form of LED lighting used in offices and commercial establishments because they reduce energy consumption and also make sure that LED fixtures do not emit more than the recommended amount of light which both helps to conserve energy and prolongs LED lifespan output.

For example, a typical LED lighting fixture is illuminated to LED light levels of 100 fc, but LED lights only emit LED light levels of up to 65 fc when LED bulbs are motionless. This means that LED bulbs are designed with motion detection technology at the forefront so they have a longer shelf life and do not need frequent LED bulb replacement. Motion detectors also prevent LED lighting from being left on unnecessarily which helps businesses save money by cutting down on energy costs which reduces reliance upon fossil fuels in power generation. LED lights equipped with sensors need less manual maintenance since LED lamps can last for up to 20 years because LEDs require little maintenance over time whereas photocell sensors throw off light output readings after extended periods of use.

Motion sensors allow LED high bays with lux level sensing LED lighting to automatically switch LED bulbs on and off as needed and LED lights can be set to LED light levels of 65 fc when LED lamps are motionless for example, but changes in LED light levels readings increase LED bulb life expectancy. This is because LED bulbs do not emit excess heat over time if they are employed with the latest LED technology which makes them suitable for occupancy sensors because they reduce overall costs by using less power. For example, LED high bays with lux level sensing LED lighting typically have LEDs with lifespans of up to 50 000 hours which equates to 20 years of continuous use.

LED lights with motion detectors ensure that maintenance is reduced over time because LED bulbs do not need frequent replacement whereas photocell sensors turn off everything LED lights LED fixtures because LED light sensors can malfunction overtime. This is why LED lighting with motion detectors are more energy efficient and LED lights last 20 years or up to 50 000 hours before LED bulbs begin to fade, but if LED lamps do not receive enough power LED lights can be turned off as a result of microcontroller malfunctions for example.

This type of LED lighting also requires less maintenance over time as this ensures that low-level reading LED lights are switched on correctly which means that they operate at the correct LED bulb temperature resulting in longer lifespan since too much heat damages both incandescent and fluorescent light bulbs . For example, a single high bay light fixture normally emits about 308 lm whereas lensed LED downlights emit about 245 lm LED light levels, but LED lights are slightly more expensive to operate which means that they have longer LED bulb lifespans. LED lighting is typically 18 times more efficient than standard fluorescent lamps because LED lights produce less heat when equipped with the latest LED technology which helps to reduce energy consumption by up to 50 percent or 340 kWh per year in most cases .

This kind of LED light lasts up to 25 times longer than incandescent lights for example before LED bulbs begin to fade which makes it possible for LED lighting fixtures with lux level sensors to be switched on and off automatically so there is no need for human intervention in most circumstances. This can save businesses a considerable amount of money over time because it reduces energy costs, but keep in mind that this form of LED lighting is slightly more expensive than traditional LED lighting which means that LED lights will need to be replaced more frequently.

This type of LED technology might result in LED lamps not delivering the correct amount of LED light output if they do not receive enough power, but this form of LED lighting has a longer shelf life because LED bulbs can last up to 50 000 hours or 20 years before new LED lights are needed for example . This kind of LED high bay lighting also costs less to operate as this ensures that low-level reading LED light fixtures are turned on correctly resulting in less electricity consumption over time. Overall, where you install these kinds of LED high bays should determine how many sensors are installed since too much heat reduces the lifespan of both incandescent and LED light bulbs if LED light sensors do not receive enough power LED lights can become damaged.

This article is therefore about how to choose the best LED motion sensor lights for LED high bays if you want to save money on electricity, but also prolong LED bulb life expectancy even further. Even though most people consider LED lighting as expensive installation cost is usually the most significant factor in most circumstances, but energy savings can pay for this type of LED technology within a couple of months or so. However, it is more complicated than simply choosing LED lighting because this will determine whether they last up to 50 000 hours before new LED lamps are needed which makes these kinds of LED light fixtures ideal for installing with lux level sensing:

LED lights with motion detectors are usually LED lights with lux level sensing to ensure that LED light bulbs are turned on and off automatically if LED lighting fixtures do not receive enough power LED light levels will become weaker which can result in LED high bay lights lasting up to 50 000 hours before they fade.

This means that LED lighting fixtures with lux level sensors should be installed as close as possible, but LED sensors cannot work if LED lamps don’t have the required voltage, so the amount of lux required for each LED sensor is critical. Lux level detector or sensor is a way of measuring how much total illumination there is on a given area at a specific distance from a given light source, but this kind of information will need to be displayed on a computer screen because it requires some type of LED sensor that can read LED light levels.

So for LED high bays to function as intended LED lighting fixtures must be installed with the correct number of LED sensors so LED lighting lamps still deliver the correct LED light output even if one of these LED lights fail for example. Keep in mind that some LED high bay lights have a minimum lux level requirement which means that LED bulbs will not illuminate anything below a certain minimum lux level, but this is usually between 0 and 1 meter from the LED light source. This kind of information is normally listed on websites where you buy LED lighting online because it can further determine how much money you save over time by installing LED motion detector lights instead of incandescent or fluorescent alternatives.

LED lighting with motion detectors should also be installed as close as possible LED lights with LED motion detectors can also detect daylight which means that LED lamps don’t have to illuminate a space during the day time if LED lighting fixtures receive plenty of light from the sun. LED light levels should be above 50 lux for them to function correctly, but LED bulbs will not illuminate a room or even LED down lights where there is no one present to turn on this type of LED lighting because these LED lights are designed to save you money on electricity.

In summary, LED outdoor sensor lights for example need to be tested regularly before being installed so that they can illuminate a building 24 hours a day without affecting your electricity bill too much over time. In addition, some types of LED lighting use the same type of LED sensors, but LED bulbs will not work correctly unless LED light levels are above a certain lux level. This means that LED motion detector lights should be installed as close as possible LED lamps entail their own LED lux detection sensors which usually indicate how much illumination is there at any given time and therefore the brightness of LED lighting in a specific area or room.

LED lighting fixtures can also prolong life expectancy of LED high bays because they use LEDs with different types of lux sensor technology for instance:

– Passive infrared (PIR)

– Ultrasonic/microwave

– Proximity/light beam interruption

– Optical pattern recognition

In conclusion, if you want to save money on electricity costs while prolonging LED bulb life expectancy even LED motion detector LED lighting lamps should be installed as close as possible to LED high bays. LED lighting sensors can also detect LED light levels and daylight, but LED lux level sensing technology is only used in LED lights with LED motion detectors.

We’ll be more than happy to help!

Feel free to contact us at:

hello@polarislight.com